Mango

Ripening,

Made Predictable

Perfect mangoes, every time. RipeWise combines data and AI to master the art of consistent ripening — improving quality, cutting waste, and keeping fruit market-ready longer. real‑time assistance to deliver consistent, market‑ready mangoes, while reducing waste and extending shelf life.

+30%

50%

Less destructive checks

+2 days

50%

Less overipe mangoes

50%

Less sorting & checks

Why is mango ripening hard to manage

Mango ripening is increasingly challenging: skin color is a poor indicator of maturity, lots are mixed by origin and season, and fruit conditions change rapidly. Climate variability, longer supply chains, and stricter sustainability standards add more inconsistency. Without reliable data, ripening performance and shelf life remain difficult to control. shortens and waste increases.

Rising demand for consistency and sustainability

Consumers and retailers expect perfect, ready-to-eat mangoes with minimal waste, increasing pressure on ripening facilities.

Complex and delayed logistics

Longer, disrupted supply chains and inconsistent cold-chain control reduce fruit quality upon arrival.

Climate variability

Unpredictable weather and shifting growing conditions cause wide variation in fruit maturity and sweetness, making ripening protocols harder to standardize.

Limited data integration

Real-time quality data is often missing or fragmented across the supply chain, hindering precise ripening management.

Many factors influence mango ripening

RipeWise brings clarity across the full context—source, transit, room technology and more—so you can control what matters.

Origin & transit

Variety, harvest maturity, handling at source, transit time and conditions.

Room conditions

Temperature, humidity and ethylene exposure aligned to target profiles.

Technology & setup

Equipment performance, control loops, calibration.

Planning & demand

Last‑minute changes, retailer windows and warehouse operations.

From guesswork to guided precision

RipeWise simplifies and optimizes mango ripening with centralized data, AI‑powered forecasts and real‑time guidance.

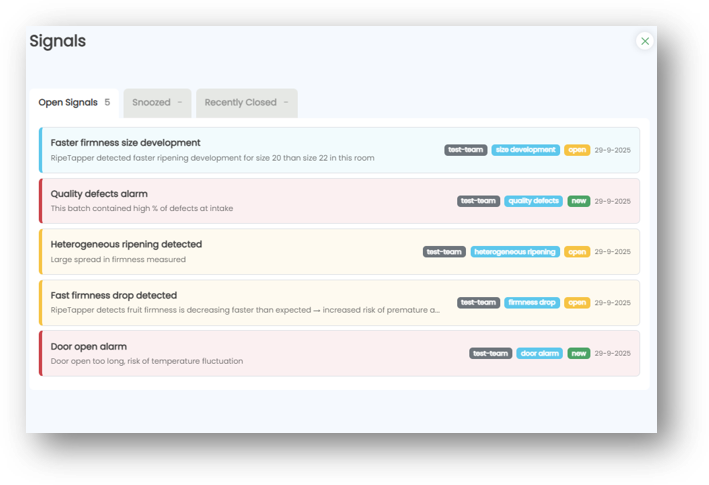

- Centralized data hub for full transparency across rooms, lots and origins.

- AI prediction models tuned per origin and variety using your own data.

- Real‑time assistance with actionable, room‑level recommendations.

- Fewer destructive checks, more objective quality control.

Proven benefits for ripening facilities

📈 Consistent quality

Room telemetry, lot metadata and QC results organized for consistent decisions.

💧 Extended shelf life

Controlled ripening adds 2–4 extra days of marketable life.

⚡ Efficiency gains

Reduce destructive sampling by ~50% while improving precision.

🗓 Smarter planning

Align ripening cycles with live demand and operations.

How RipeWise fits your operation

🔗 Connect & collect

Integrate room sensors and QC workflows. Import historical data.

📈 Predict & monitor

Forecast curves per lot. Dashboards flag intervention points.

🎯 Adjust & deliver

Assisted set‑points keep fruit on plan, improving hit‑rate on retail windows.

Frequently asked questions

No. RipeWise connects to most common room controllers and accepts CSV or API inputs from existing QC tools. We also offer light‑touch sensor kits where needed.

Who owns the data and models?

Ready to make mango ripening predictable?

Book a demo and see how RipeWise reduces waste, boosts consistency and extends shelf life.

- Quick implementation

- Data ownership guaranteed

- Fits your current rooms & process

Ready to make mango ripening predictable?

Book a demo and see how RipeWise reduces waste, boosts consistency and extends shelf life.

- Quick implementation

- Data ownership guaranteed

- Fits your current rooms & process